Cambustion releases new generation of our DPG particle filter test solution

We have released a new generation of our DPG diesel and gasoline particulate filter (DPF / GPF) test solution, expanding its use to medium and lower volume engine and vehicle manufacturers.

The new baseline model of our particle filter test solution improves performance analysis and development of exhaust equipment in the heavy-duty industrial market. The technology is a condensed model of our original particle filter test system which is widely accepted as the industry standard solution for end of line quality assurance and development testing of particle filters in the mainstream automotive market, where it is used by all of the major exhaust manufacturers in the world.

The solution retains the core features of the original technology in a lower-cost adaptation designed to support industrial engine manufacturers and engine aftertreatment companies as they work to meet increasing global regulations on particle number and particle mass emissions for vehicles used in the agricultural, construction and mining industries, as well as ships, trains and aircraft.

“Our original DPG solution is an exceptionally well-developed technology with a proven track record of almost two decades. The system has been adopted by all the leading automotive aftertreatment manufacturers in the world and is used to test filter technologies for most mainstream vehicles on the road today.

We’ve now streamlined the technology in order to reduce costs without compromising on essential capability. In this way, we’ve made the solution accessible to manufacturers and aftertreatment companies in the heavy-duty industrial markets as they address the challenge of measuring and improving the performance of particle filter technologies.”

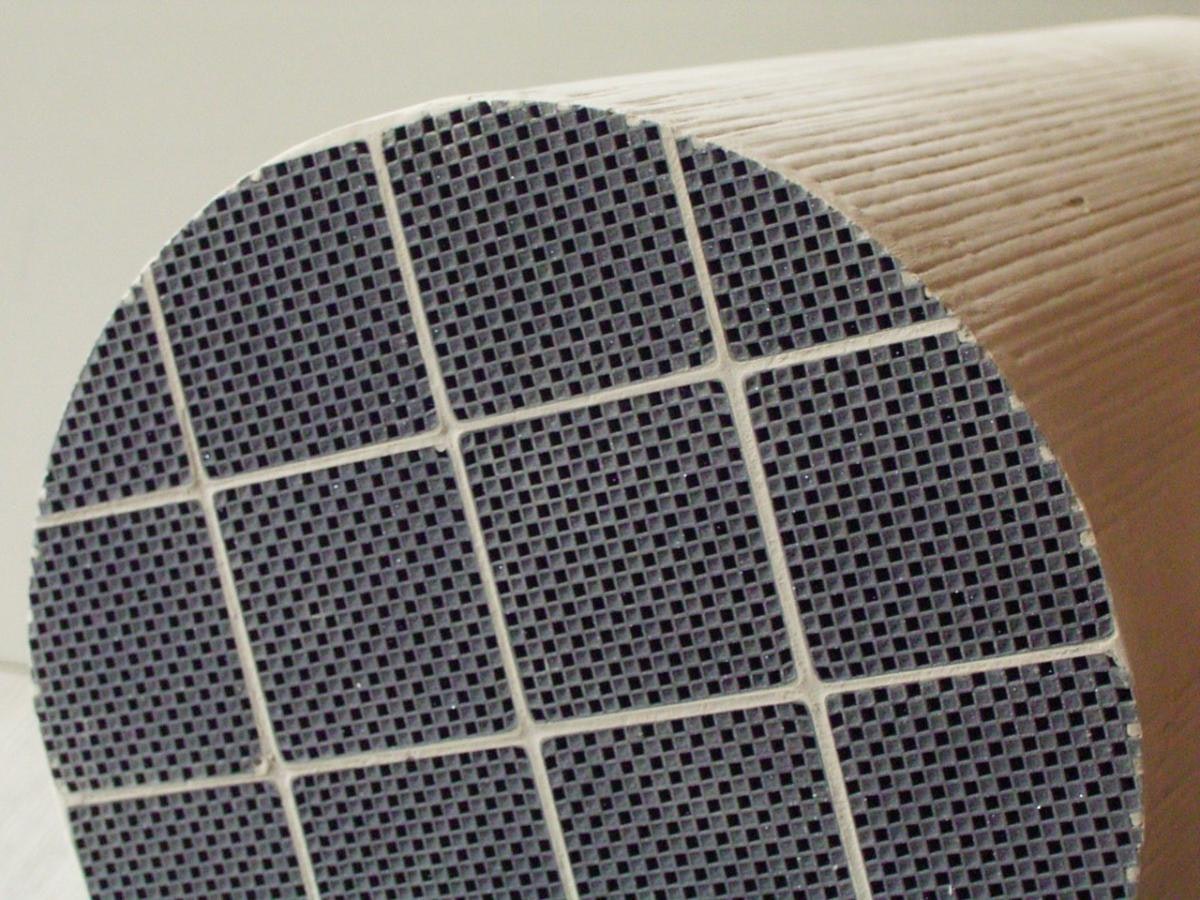

Filtration efficiency measurement with the DPG

The equipment is designed to test the DPF or GPF to its limits while simultaneously measuring and recording essential performance data. Engine manufacturers can use the data to support product development and improve the performance and durability of their exhaust technologies.

“The DPG system can confirm filtration efficiency – the only equipment that can do this at the full operating flow and temperature of the filter. It can controllably load the filter with soot and ash and measure how this affects the backpressure and filtration efficiency. The system can simulate soot regenerations, checking the robustness of the filter and simulating full lifecycles dramatically faster and more economically than with engine testing.”

Find out more on the DPG webpage.