AF10 | Aerosol Flowmeter

Designed for the measurement of particle laden flow

The Cambustion Aerosol Flowmeter is compatible with solid, liquid, and mixed aerosol particles suspended in a wide range of gases.

Unlike other popular flowmeters, the AF10 is not damaged by aerosol particles and it does not modify the properties of the aerosol. It uses the well-established measurement principle of pressure drop across an orifice, with simultaneous measurement of absolute pressure and temperature for density correction.

An integrated cleaning brush ensures that flow readings remain accurate even over long experiments, and the optimised flow path design ensures minimal losses across particle sizes.

Thanks to a set of interchangeable orifices, the AF10 covers a wide range of flows (0.1 - 10 lpm) and is suitable for use with many common laboratory instruments, including CPCs.

Features

The AF10 operates out of the box to measure online aerosol flows in a broad range of applications.

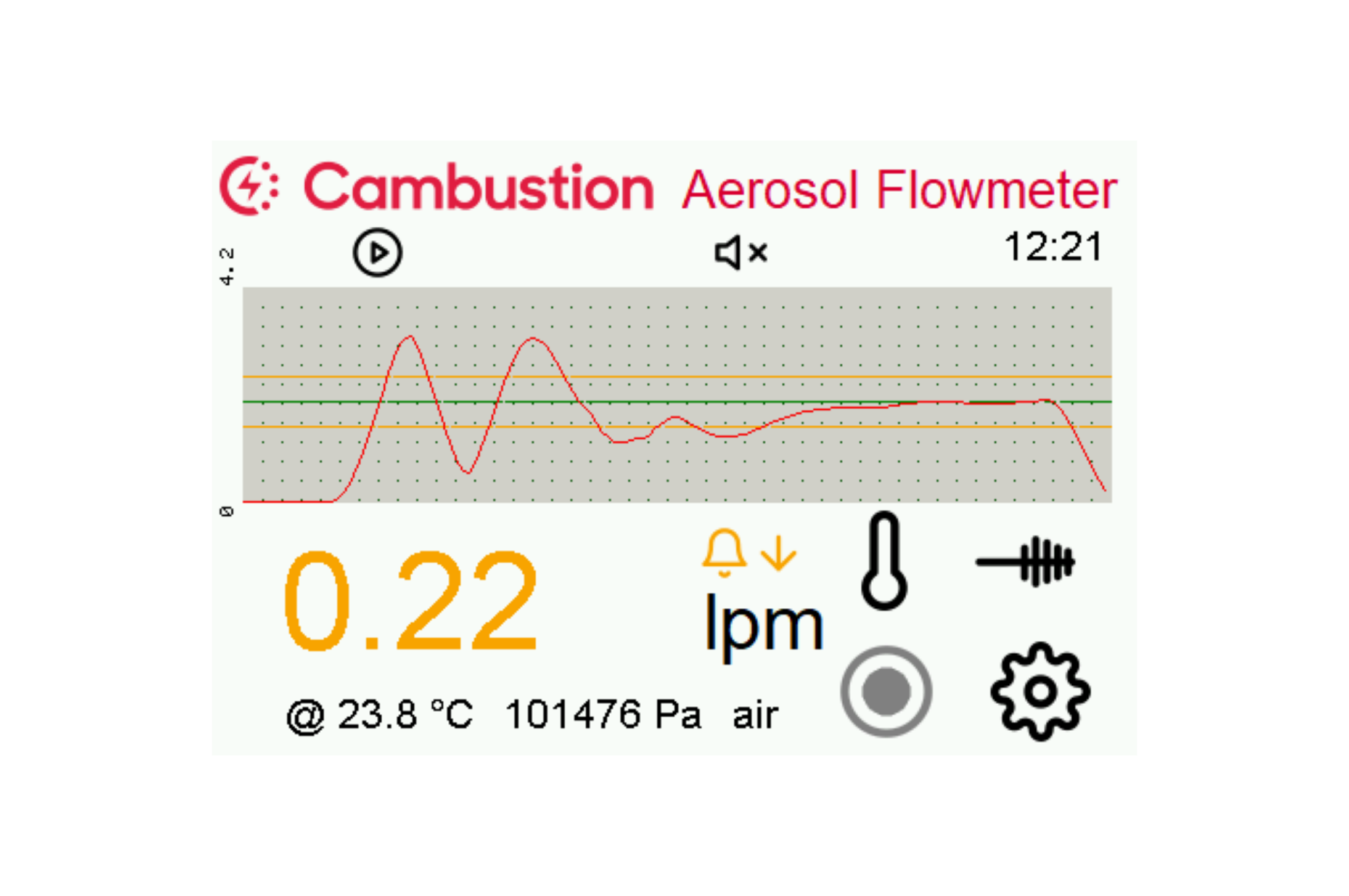

To facilitate monitoring of complex experiments, flow deviation alarms can be set to notify the user when the measured flow is outside specified boundaries, making sure any malfunctions in the experimental setup do not go undetected.

Flows are automatically corrected for temperature and pressure and can be referenced to any user-specified conditions, facilitating the comparison with both mass and volumetric nominal flows.

Besides communicating directly with other Cambustion instruments such as the AAC, CPMA and the UDAC, the AF10 integrates seamlessly into many common experimental set-ups, thanks to standard analogue output and Ethernet interfaces. Power is via USB for portability and convenience, and data can be logged to a USB flash drive for future analysis.

The AF10 can be operated via the intuitive touch-screen interface, or via remote control for more complex experiments. Additionally, a strong portable case and the ability to run off a standard power bank make it an asset during field campaigns.

Why do flows matter in aerosol science?

Many important metrics are expressed in terms of particles in a volume of gas (#/cm^3 or μg/m^3).

If the temperature or pressure change, the same mass of gas (containing the same particles) will occupy a different volume.

Therefore, when comparing “per cm^3” measurements between different instruments, the cm^3 might be different if the conditions are not the same!

As a consequence, when all the instruments in an experimental setup are operating correctly, different flow measurement methods (mass flow vs volumetric flow) between instruments can introduce variability from one day to the other, with changes up to a few percent.

But often, in real experiments, even the flows which are assumed fixed can drift – and affect the measurements to a much greater extent.

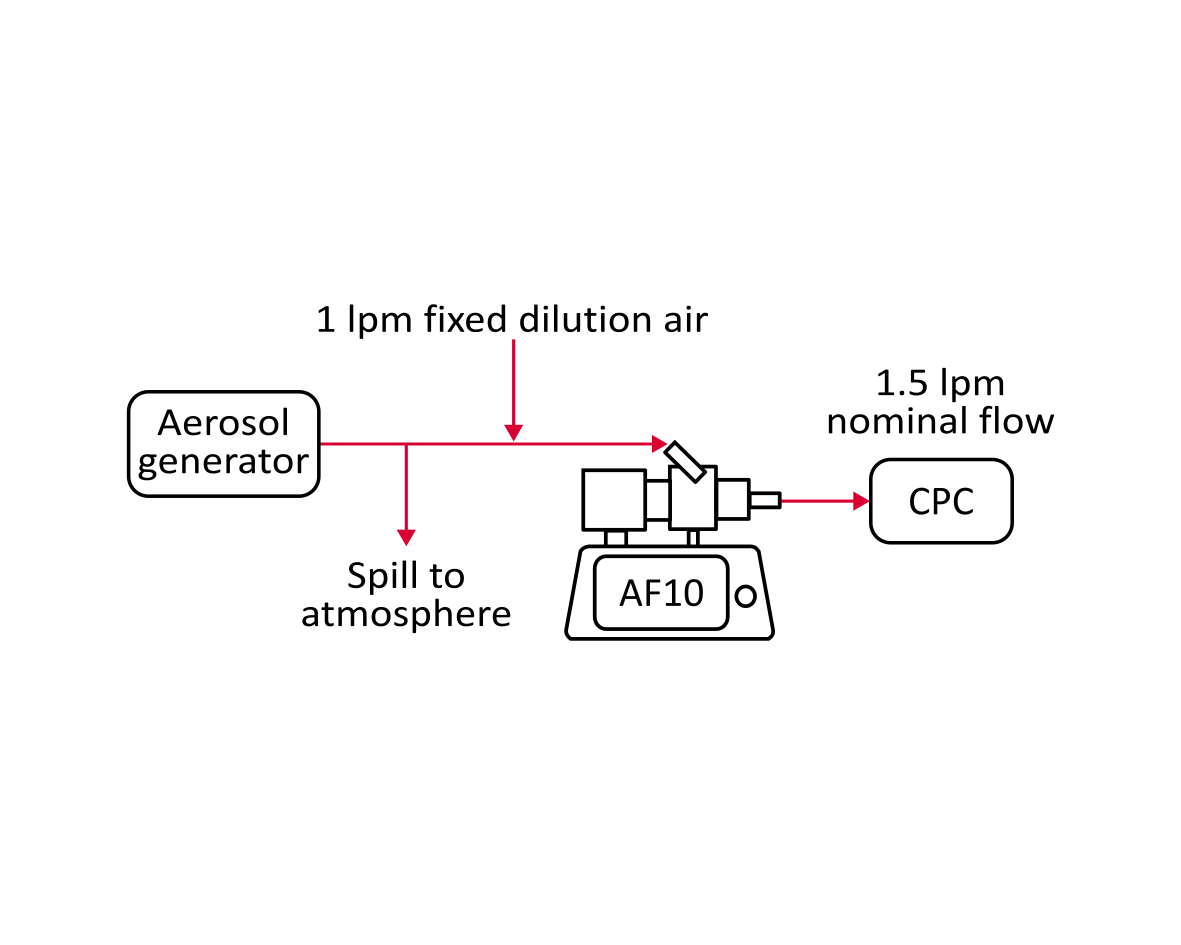

Consider a CPC measuring from an aerosol source with upstream dilution, as in the image:

A change in CPC flow will affect the measurement.

Even if the CPC corrects its output to account for the flow difference, the upstream dilution will change and result in a measurement error.

Real-time monitoring of the flow with the AF10 can be used to adjust the dilution flow as the CPC flow varies, or to calculate the true dilution. Flow deviation alarms on the AF10 can help ensure that significant deviations do not go undetected, and improve the repeatability between experiments.

Applications

The AF10 can help improve the accuracy and repeatability of many experiments by measuring directly the aerosol flow rate of interest. From use with aerosol classifiers (where the sample flow rate sets the resolution), to monitoring of generators output or CPCs input.

Dilution bridge

Amongst others, the AF10 can be used in dilution bridges, where knowledge of the aerosol flow rate is particularly important to achieve a stable dilution. A widespread issue when using dilution bridges is that the valve exposed to aerosol flow clogs up as particles deposit, causing the dilution to increase over time. Standard gas flowmeters would normally be placed downstream of the HEPA filter in the particle-free flow, but in high dilution applications, accurate measurement of the particle free flow does not allow accurate calculation of the bypass (aerosol) flow due to the large ratio between the flows. It is thus difficult to correct for drift without real-time knowledge of the bypass flow. The AF10 can directly monitor the flow through the aerosol-laden branch, significantly increasing the accuracy in case of high dilution ( Y << X ) and allowing the user to compensate for any drift in the system.

AF10 Aerosol Flowmeter brochure

Download a brochure, or contact Cambustion for further information and prices.

Need more information? Connect to an expert