Heat not burn material test system

Heat not burn technology

The global market increasingly features products using electrical heating to warm a consumable such as tobacco (Heated Tobacco Products, HTP) or cannabis flower (dry herb vaporisers) as an alternative to combustion.

The tobacco or cannabis does not reach the high temperatures achieved during combustion, and accurate control of the heating process is essential.

Material testing & device development

Since the technology of heat not burn offers developers greater choice regarding device heating strategy and treatment of consumables, the ability to test small quantities of loose material (e.g. tobacco or cannabis flower) without requiring the material to be fully processed into consumer products is convenient.

When developing a new heat not burn device, the designers have great flexibility regarding heating strategy. To inform this strategy, the ability to test samples of loose material (e.g. tobacco or cannabis), while retaining total flexibility regarding heating rate is attractive.

It should be possible to capture vapours and aerosol for offline analysis, or even measure online in real-time. Evaluation of taste and mouthfeel also forms a key part of the user experience and evaluation of this should be supported.

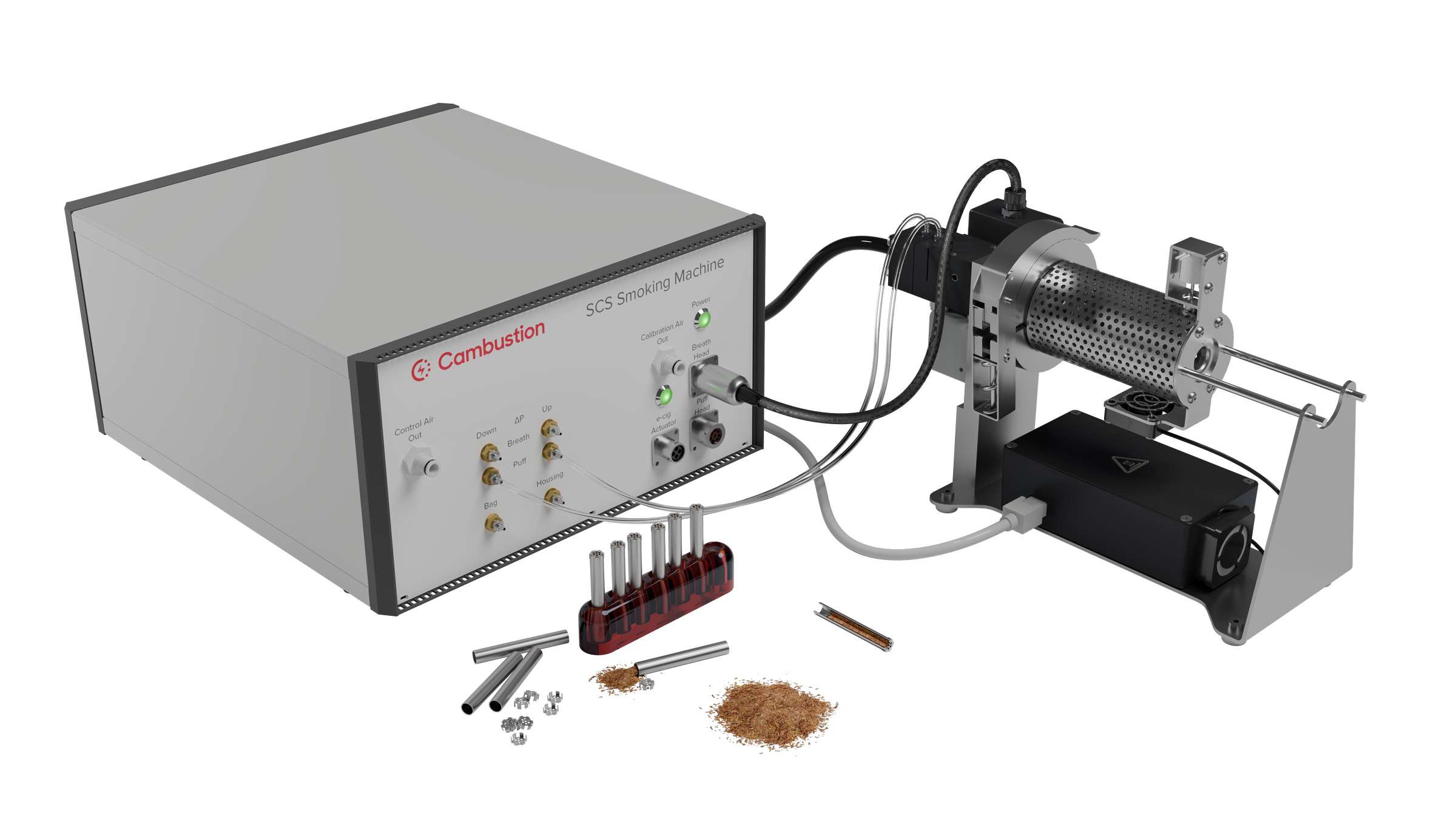

SCS smoking & vaping machine

Cambustion's SCS is a continously evolved (since 2004) programmable smoking and vaping machine with applications in research, product development and Quality Control.

The standard SCS allows the user to pre-programme flow rate vs time profiles for repeatable testing. Gases and aerosol from samples under test are available for on- and off-line analysis, while the SCS records all test parameters including flow rates, temperatures and pressure drops.

TCT - tobacco & cannabis tester

The TCT is a fully integrated accessory for the SCS, developed to address industry needs.

The novel TCT allows the testing of small amounts (~2g) of loose tobacco or cannabis flower in accordance with heat not burn principles, without requiring either final consumables or full product development.

The user defines a temperature vs time profile for the sample, which the TCT reproduces using a highly controllable induction heating system.

The temperature profile may be as straightforward as a single temperature setpoint, or a more complex temperature vs time heating curve.

The user has flexibility regarding the alignment of the heating profile with the flow profile - so the effects of pre-heating the sample prior to drawing flow may be fully investigated.

Typical test process

A test sample of loose material is loaded into a stainless steel carrier, and held in place with a cap.

The carrier is loaded into the TCT accessory, which is integrated with the SCS.

The user selects the test profile. The flow aspect is reproduced by the SCS while the TCT reproduces the required temperature profile.

When the user clicks Play, the TCT and SCS work together to heat the sample and draw flow.

The SCS and TCT record performance data as the profile runs, and produce both data logs and a configurable PDF report.

After the test ends, the sample is cooled and the carrier may be removed from the TCT either for further material analysis or disposal of the contents.

Taste & mouthfeel

The TCT also offers users direct access to the gases and aerosol for taste and mouthfeel evaluation.

TCT brochure

To understand more download the TCT brochure and contact Cambustion to discuss your application.

Need more information? Connect to an expert